The Woodturner's

Workshop

Home

Book Review: 1

The Pole Lathe Plans Book

by

Mark Pottinger

Soft back, 48 pages, 25 black and white pictures.

ISBN 0-9546189-2-0

Price: £8.50 (Postage 85p) from:

DESUK Ltd - Book Order

28 Oldaker Road

Newick

Lewes

East Sussex, Bn8 4LW

|

|

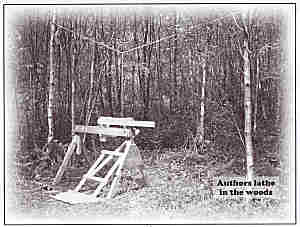

Some years ago Mark Pottingeran his wife managed

to fulfil a lifetime ambition of owning their own wood. This

gave them the opportunity to try various activities including

making their own charcoal, birch sap wine and trying wood

turning on their own pole lathe. The lathe he designed, the

plans of which are set out in this book, is shown alongside.

This can be made from readily available materials. The author

used recycled material such as hardwood from heavy duty pallets

and plywood from industrial packing cases. Some of the

dimensions shown in the plans may have to be modified to suit

the materials at hand.

The pole lathe is a foot operated reciprocating lathe. A cord

is attached to a treadle at one end and to an elastic device or

spring at the other. The cord is also wrapped around the

workpiece for a couple of turns. When the treadle is depressed

the workpiece, which is held between two fixed points, rotates

towards the cutting tool - when the treadle is released the

spring turns it in the opposite direction. The name Pole

Lathe is derived from the fact that a long pole was

traditionally used used as a spring to provide the return

stroke. The pole is still used by some turners but others find

alternatives, such as bungee cord, more convenient. The lower

image on the left, taken from the plans, shows how a pole can

be set up.

For anyone wishing to build their own pole lathe this book

provides a clear and detailed set of plans. This lathe has a

fixed headstock with a movable "poppet" (tailstock). Some pole

lathe turners prefer to have two movable poppets and dispense

with the fixed headstock. This is not a problem - if two

poppets are required it is a simple matter to duplicate the one

in the plans and to fit it with a fixed centre.

The height of this lathe is fixed at a relatively low level.

Many makers will want a taller machine. How should they

determine the height of the machine? This poses a problem

because that there is no ideal relationship between the height

of the lathe centres and the height of the operator. Taller

people are likely to need a taller lath but even two people of

the same height may prefer different bed (or poppet) heights. I

would suggest that the aim should be to make it so that the

bottom of the bed is at hip height. In my case, being 5 ft 6

ins tall, that is 36 ins. That enables me to raise my thigh so

that it is parallel to the ground - and should be the maximum

required. This is a few inches higher than these plans suggest

but if it is found to be too high it is easier to shorten the

legs than to make them longer.

A pole lathe is a much safer machine to use than a powered

lathe and provides a very good means of introducing woodturning

to children. If, there is a chance that children may wish to

use the lathe then it might be better to make the legs

relatively short and to bolt on extension pieces as required.

This design is relatively light in weight. It can readily be

broken down into manageable sub-assemblies which makes it easy

to store and to transport. The protype was designed for use in

a wood, very much as it might have been by turners in the past.

However, one built from these plans can be used on a few square

feet of land if bungee cord is used for the spring instead of a

pole. So it can be used in most people's back garden.

Only some very basic instructions in the use of a pole lathe

are given in the book but the author suggests that anyone new

to this craft should take a course of instruction. He explains

that plenty of these, run by various woodland groups, are

available. If people go on a course they should have the

opportunity to find out the height of then lathe which suits

them best. |

Some historical notes

|

|

It is interesting to note how little the pole lathe has

changed over at least 350 years. The image on the left is taken

from a plate in a book by Joseph Moxon. The title of this is:

Mechanick Exercises or the Doctrine of Handy-Works which

was first published in 1678. The pole lathe had, however, been

in use for a long time prior to Moxon's day. We know this

because there is a stained glass window in Chartres Cathedral,

donated by the local guild of turners in the 13th century, that

shows a turner working on, what appears to be, a pole lathe.

This depiction is not absolutely clear but there is a

manuscript miniature from the same period which shows a turner

at work on what is undoubtedly a pole lathe. The turner and his

(her?) companions are wearing not only what appear to be monks

habits but, strangely, a wimple as well!

An Egyptian wall carving shows that lathes operated with a

strap wound round the workpiece (but without a spring) existed

as long ago as the 3rd century BC. Physical evidence of turned

items has been found which shows that turning took place long

before that. A remant of a bowls has been unearthed in Northern

Italy which is dated as from the 7th century BC. Many more

turned pieces have been found that were made between the 7th

and the 3rd century BC. It is reasonable to think that lathes

similar to that shown in the Egyptian carving were used in the

earlier period but that supposition cannot be proven.

To return to Moxon's illustration: the horizontal bar in the

foreground of the plate was called the seat. Moxon says that

"It is not called a seat, because it is so; but because the

Workman places the upper part of his Buttocks against it, that

he may stand the steadier to his work, and consequently guide

his Foot the firmer and exacter." We might also think it would

make it easier to control the tool. Turners using the seat are

shown in a number of old photographs but I am not aware that

any pole lathe turner uses it today. |

|